Column Packing materials and resin:

Column: BXK100/950

Column diameters: 100mm

Packing reservoir: BXK100

Resin: Bestarose 4FF Lot: 2019072401

1. Get the equipment prepared. Calculate the volume of resin required: dry gel/1.15= the intentional packing volume.

Dry up the resin(when the gel surface is dry), weigh 5420g of resin and add water till 10.8L. Mix evenly with a stirrer and pour solution to the column.

Keep column still for 60min till 1-2cm supernatant appears. Drain the bubble in the adaptor sieve and mount the adaptor. Drain the bubbles in adaptor O-ring and seal the O-ring.

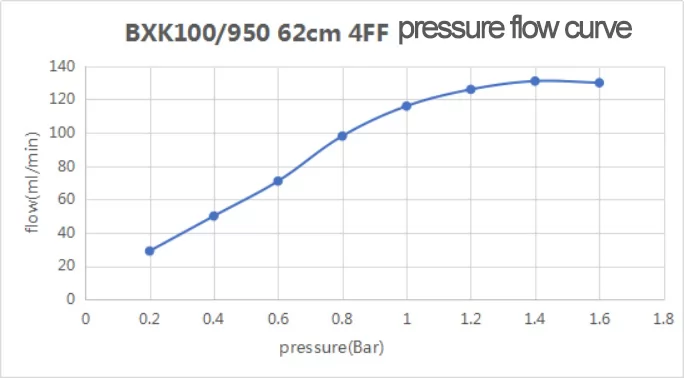

2. Set the pressure at 1Bar, open the column up and lower valves. Press column for 30min(gel bed height: 65cm flow rate :140 ml/min).

3. Turn off the flow rate, shut lower valve, remove the adaptor. Drain the liquid in the reservoir and remove it . Keep on draining the column solution till the liquid level is 10cm above the gel surface. Mount the adaptor, drain bubbles and seal the O-ring.

4. Press column with 1Bar, open the upper and lower valves, press column for 40min till gel bed is stable for 10min(gel bed height : 62.5 cm; flow rate: 125ml/min; This flow rate can be used for the column packing at constant flow rate)

5. Turn off the flow rate. Swiftly press the adaptor to the point 0.5cm below the gel surface. Column bed height: 62cm, flow phase: water, Column efficiency test: load 1% CV(48ml) of 1% acetone, set flow rate at 0.5cm/min, column efficiency: 4897N/m

Note: the optimum flow rate may vary from different column heights and diameters concerned. Get your own optimum flow rate via practical experiments.

.png)