Column Packing materials and resin:

Column: BXK16/70

Column diameters: 16mm

Packing reservoir: BXK16/70

Resin: Chromdex Lot: 2019030401

1. Get experiments devices prepared. Calculate the volume of resin required: dry gel/1.15= initial packing volume (60cm). Replace ethanol preservation solution with distilled water. Weigh 130g dry resin and add distilled water till 280ml (slurry concentration:48%). Stir well with glass rod and set for use.

Connect to AKTA and remove the upper adaptor sieve bubbles for use; Remove bubbles in lower adaptor sieve; mount adaptor on column and fix it on stand. Horizontally calibrate the column and pour the slurry to it. Mount the adaptor and press column.

2. Set flow rate at 3ml/min, open the column lower valve, press column for 90min till the resin bed is 68cm.

3. Turn off the flow rate. Shut the column lower valve and disconnect the upper adaptor. Drain the liquid in the reservoir and disconnect it. Mount the upper adaptor on the column, seal the O-ring.

4. Set pressure at 5.7Bar and keep the pressure unchanged. Open the column lower valve and press column for 40 min. The resin bed height is 62.5 cm.

5. Turn off the flow rate. Swiftly(less than 10 seconds) press the adaptor to the resin to a point 0.5cm lower than its original bed height. Final column bed height will be 62cm.

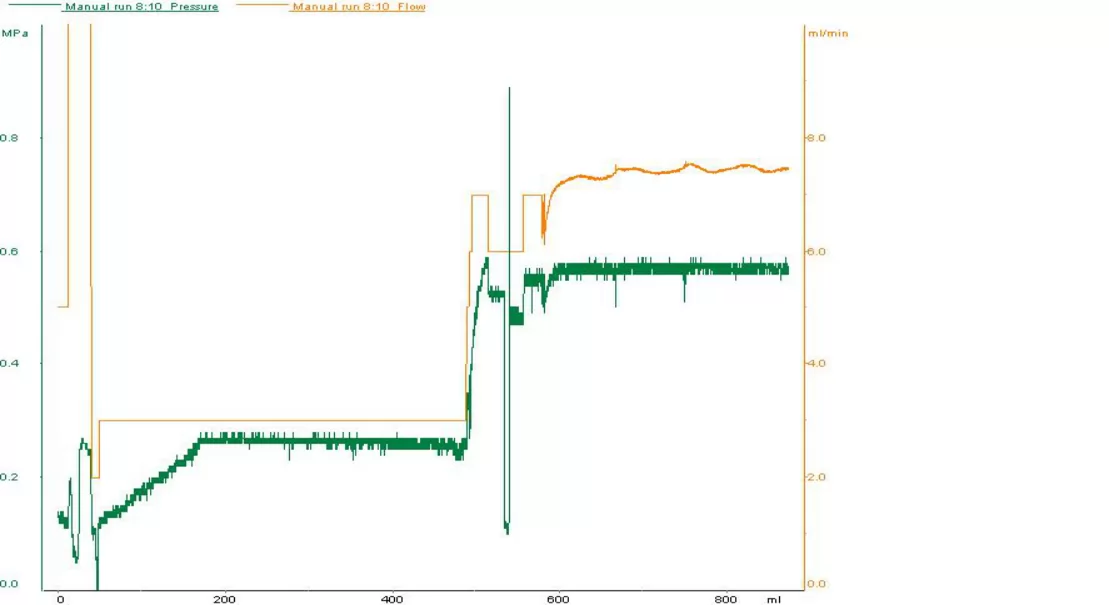

Pressure and flow rate during the column packing process.

Mobile phase: water

Load 1% CV(1ml) of 1% acetone

Flow rate: 0.5cm/min

Result: column efficiency: 11820N/m

Note: the optimum flow rate may vary from different column heights and diameters concerned. Get your own optimum flow rate via practical experiments.

.png)