In the sector of large molecule preparation including vaccine, gene therapy and exosomes, efficient removal of impurities, while keeping high recovery and easy scale-up remains a key challenge in the development of downstream processing.

Diamond Layer mixed-mode resins, are born as a solution to this.

The working mechanism of double-layer structure

Layer resin beads consist of two parts: core bead and a porous shell:

-

Core bead: highly rigid agarose beads with ligands being coupled, possessing both IEX and HIC interactions.

-

Porous shell: ligand-free, function as size exclusion chromatography(SEC), control the sizes of molecules entering into pores based on molecular weights of bio-molecules.

Double-filtration mechanism’ in purification:

-

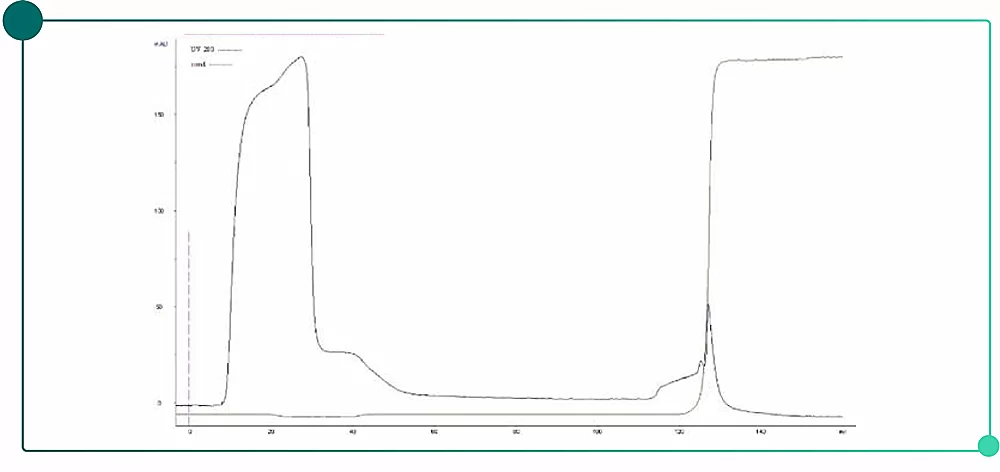

Large bio-molecules(e.g. viruses, VLP, plasmid)---blocked by shell and flow through.

-

Small molecule impurities----enter into pores of beads, interact with ligands and bind.

The core-shell design provides Layer resins with dual functions of SEC+chemical adsorption.

Core advantage

Compared with traditional SEC or single-mode resins, Layer resins enjoy advantages as following:

• Impurity removal via single-step operation, wide condition

-

Target molecules flow through, impurities bind via HIC/IEX interaction.

-

Suitable for wider range of pH and salinity, higher adaptability.

• High throughput, high efficiency

-

High flow, low back pressure, no need to have high bed height (compared with SEC resin), applicable for large scale production.

-

Large sample volume, adsorption of high volume of impurities, effectively cut CV and operation time.

• Stable structure, better tolerance to cleaning using common chemical reagents.

High mechanicastrength, good chemical stability, can tolerate CIP with 1M NaOH + 30% isopropano

• Better scalability

Easy to scale up from lab experiment to commercial production, shorten up production process development period.

Applications

Layer resins enjoy outstanding performance in the downstream bioprocessing:

• Vaccines for human: widely applicable to the purification of viruses, plasmid and VLPs.

• Cell and gene therapy: efficient removal of impurities from the extraction of plasmid to capture of viral vectors. A good replacement for conventional SEC resins.

• Vaccines for animal and other sectors: 90% and above recovery for PRRSv (Porcine Reproductive and Respiratory Syndrome virus ) vaccine. Suitable for extraction of exosomes from different sources, suitable for large volume feedstock, easy scale-up.

Case Study

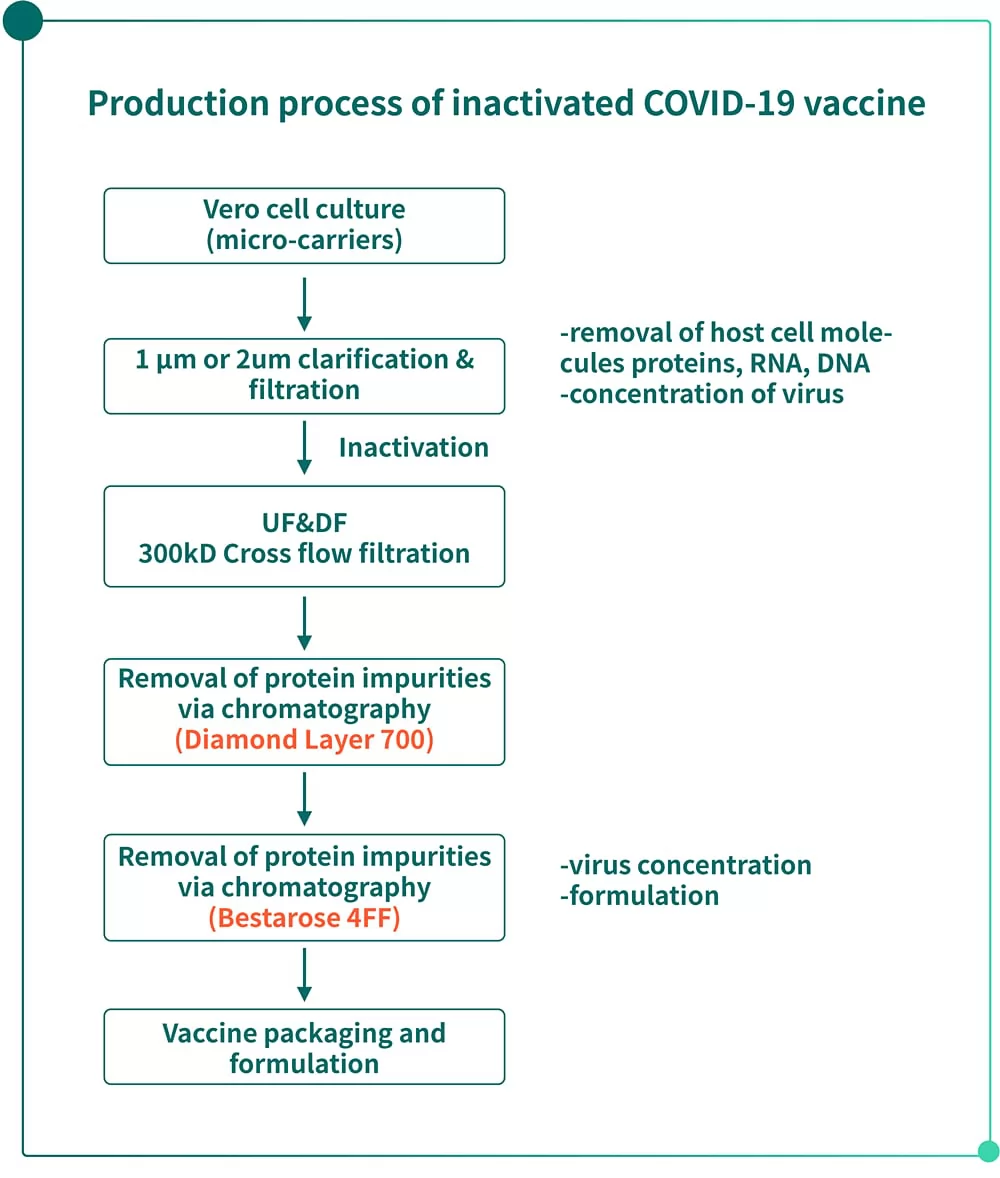

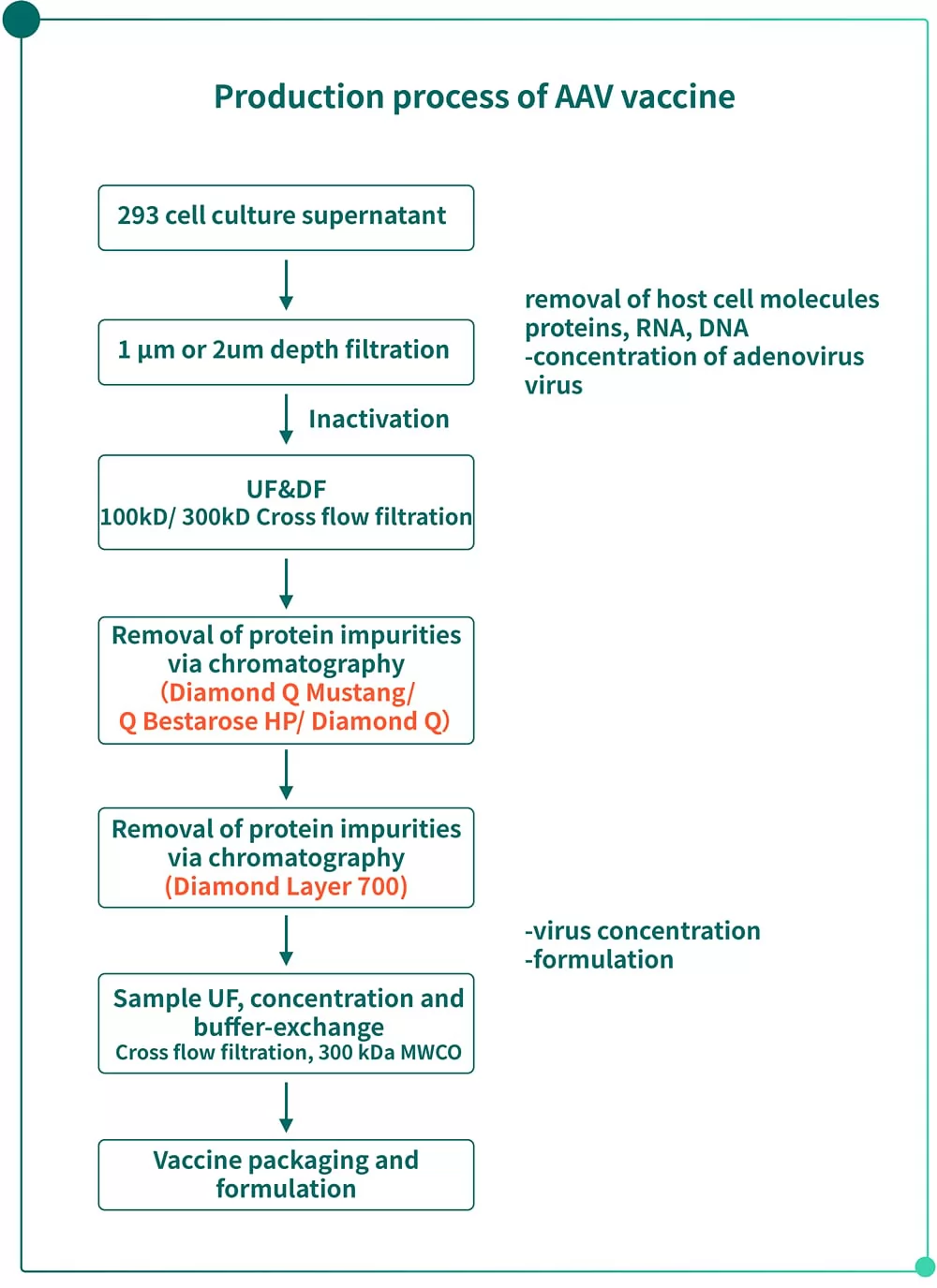

• Inactivated COVID-19 vaccine: remove HCP and DNA via single-step purification, keep activity of antigen.

• AAV vaccine: High flow operation, shorter purification time.

• Lentivirus purification: when level of impurity is low, recovery of 60% and above is achievable via single-step purification using Layer resins.

|

Step |

Condition |

|---|

|

Equilibration |

pH7.0-8.0 |

|

Wash |

Same as equilibration buffer |

|

CIP |

1M NaOH+30% isopropanol |

|

Normally, when conditions of upstream impurities are relatively good, LVV can get a 60%+ recovery via single-step purification using mixed-mode resin. |

Conclusion

Layer mixed-mode resins combine the SEC interaction and chemical adsorption, realizing efficient impurity removal and easy scale-up while ensuring high recovery of target molecules. All these provide new options for the preparation of vaccine, gene therapy and exosomes.

Order Information

|

Resin |

Pack size |

Cat.No |

|---|

|

Diamond Layer 700 |

25mL |

AI0461 |

.png)