Option for Efficient Antibody purification AT Protein A Diamond Ultra

1. Background Information

The past few years have witnessed a rise in cancer rate and therefore the development in cancer therapy. According to the list of top-selling drugs worldwide, antibody-based drugs play a dominant role in the market with an ever increasing demand in oncology sector. Meanwhile, Antibody conjugating drug(ADC) has gained extensive attraction for its great potential in targeted cancer therapy.

Protein A affinity resin, a key participant in antibody purification stage, plays an vital role in the production of antibody based drugs. Due to the optimization in upstream process and constant increase in expression volume, higher demand has been posed on downstream bioprocessing. Despite of its stable performance, conventional Protein A resins suffer from disadvantages such as low productivity and high cost in the purification of antibody with high expression.

To better meet market demand of higher cost-efficiency in process, Besthcrom launched our latest recombinant alkali tolerant Protein A affinity resin- AT Protein A Diamond Ultra.

2. Product Introduction

AT Protein A Diamond Ultra affinity resin is innovative Protein A affinity resin obtained by coupling recombinant alkali tolerant Protein A ligands on high rigid agarose beads. It is applicable in the purification of bio-macromolecules including monoclonal antibody, bispecific antibody, polyclonal antibody and Fc fusion proteins.

Compared with AT Protein A Diamond Plus, AT Protein A Diamond Ultra enjoys higher DBC(≥75mg human IgG/mL resin). Thus, AT Protein A Diamond Ultra serves as an ideal option for purification applications ranging from lab-scale trials to process scale projects.

Table 1. Technical parameters comparison between AT Protein A Diamond Ultra and AT Protein A Diamond Plus

|

Resin |

AT Protein A Diamond Ultra |

AT Protein A Diamond Plus |

|

Matrix |

High rigidity agarose |

|

Functional group |

Recombinant Alkali Tolerant Protein A |

|

Cross-linking method |

Epoxy chemistry |

|

Particle size D50+ |

~60μm |

~75μm |

|

Dynamic binding capacity ++ |

≥75mg human IgG/mL resin |

≥60mg human IgG/mL resin |

|

Max. pressure |

0.5MPa |

|

Max flow |

≥200cm/h

0.1MPa, BXK300, h=20cm, 20℃ |

≥250cm/h

0.1MPa, BXK300, h=20cm, 20℃ |

|

Alkali tolerance |

0.1-0.5M NaOH |

|

pH stability |

3-12(working) 2-13(CIP) |

|

Storage |

20% ethnaol,2-8℃ |

+The particle size is normally distributed, the particle size of the D50 value means that the sum of particle volumes smaller than this particle size is the same as the sum of particle volumes greater than this particle size

++ DBC detection uses 3mg/mL IV human IgG in PBS buffer, residence time is 6 min, get DBC at 10% breakthrough.

3.Advantages of AT Protein A Diamond Ultra

High DBC, good alkali tolerance: Effectively cut resin consumption, longer resin life cycle, lower production cost.

Low back pressure, high flow rate: better pressure/flow performance, improved productivity, suitable for process scale application.

Good lot-to-lot consistency: mature technology and stable process, ensure stable product quality and production operation.

High DBC, good alkali tolerance

The optimized Protein A ligand concentration provides high DBC for AT Protein A Diamond Ultra . The recombinant Protein A ligands offers better alkali tolerance for resin, enabling CIP with 0.1~0.5M NaOH.

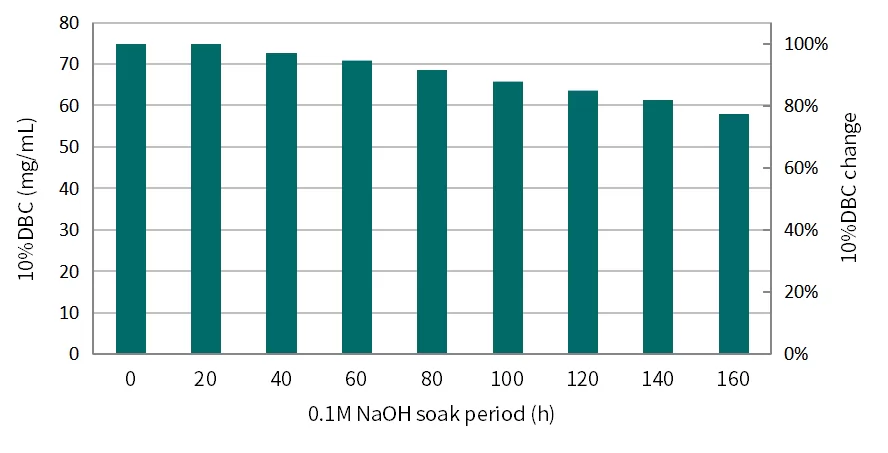

Take human IgG antibody as example, soak sample in 0.1M NaOH at 23℃. Take sample out every 20 hours for 10%DBC detection. Total soaking period is 160 hours. As illustrated(Fig.1), T Protein A Diamond Ultra resin has an initial 10% DBC at 75mg/mL. Its 10% DBC can still be 80% of its initial level after being soaked in 0.1M NaOH for 140 hours.

The high DBC and good alkali-tolerance of AT Protein A Diamond Ultra resin can effectively reduce resin consumption and increase resin life cycles, effectively reducing production cost and raising productivity.

Fig.1 resin processed with 0.1 M NaOH, 10% DBC

Column: EzScreen 4.6mL; Sample: Human IgG; residence time: 6 min

Column efficiency: As 1.09/7106 (before alkali processing ); As 1.15/7041(after processing with alkali for 160 h)

Low back pressure, high flow rate

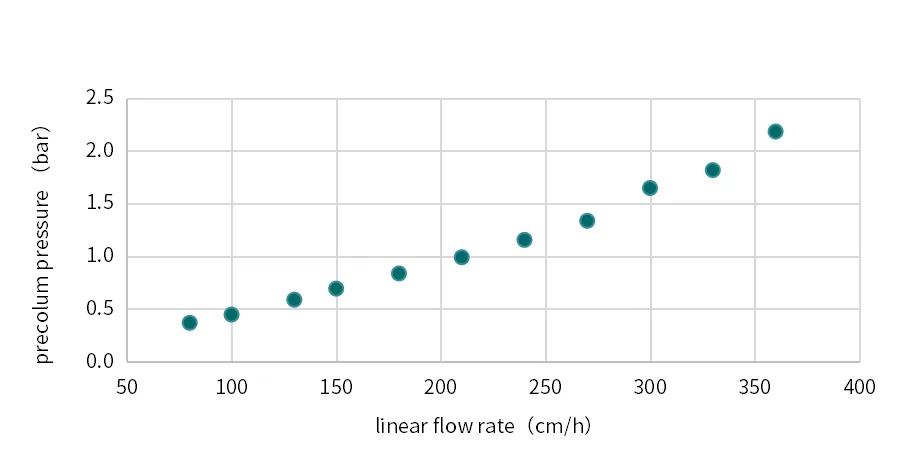

AT Protein A Diamond Ultra is based on high rigid agarose beads with excellent mechanical resistance. The resin enjoys excellent performance in pressure/flow under wide linear flow range, providing advantages including low back pressure and high flow rate.

As illustrated by Fig.2, use column (600mm*26cm), use 1M NaCl as mobile phase for the detection. When flow rate is 360cm/h, column pressure is 2.183 bar.

The pressure/flow characteristics and stable bed height of AT Protein A Diamond Ultra will facilitate scale-up processing, boosting proficiency of antibody and Fc protein purification, reducing resources input in equipment and time, dramatically cutting production cost.

Fig.2 AT Protein A Diamond Ultra column pressure/flow curve (mobile phase 1M NaCl)

Column diameter: 60mm; Column bed height: 26cm

Lot-to-lot consistency

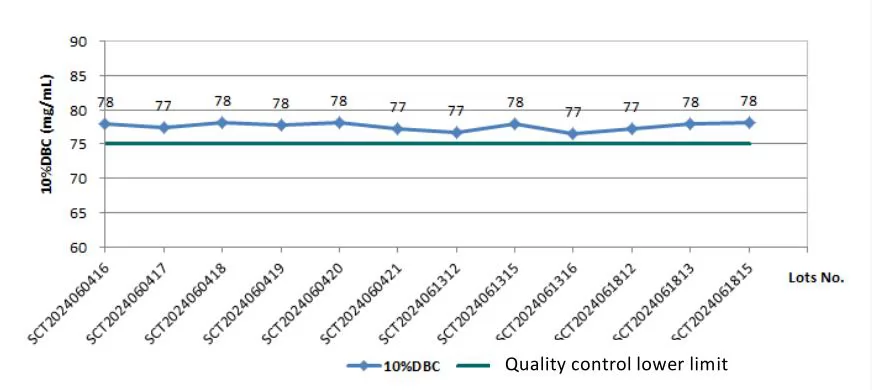

By comparison between 10% DBC detection and antibody purification experiment, lot-to-lot consistency detection of AT Protein A Diamond Ultra affinity resin is carried out.

Fig.3 Lot-to-lot consistency of resin (10% DBC)

Sample: human IgG residence time: 6min

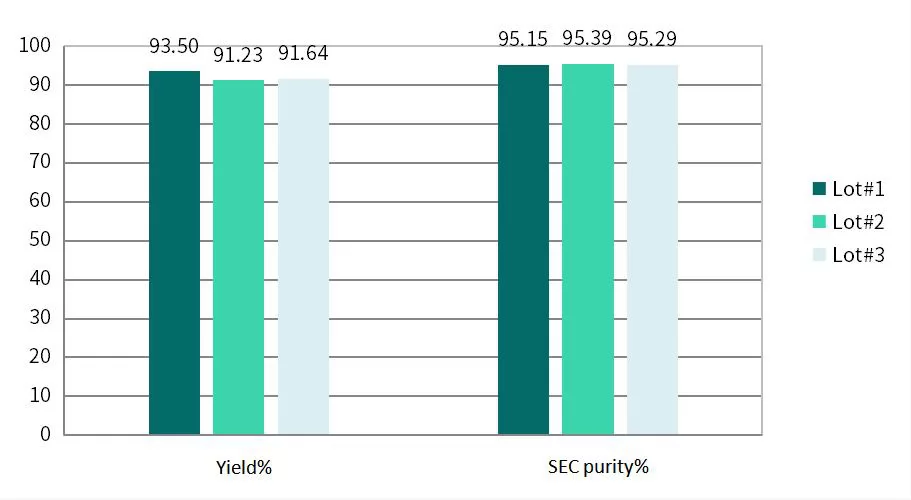

Fig.4 Comparison results between resins from different batches

Column: EzScreen 4.6mLl; Sample: mAb IgG2; Residence time: 6min; Sample loading volume: 58mg/mL

As illustrated, AT Protein A Diamond Ultra resin will facilitate the construction of robust supply chain via its excellent lot-to-lot consistency.

4.Conclusion

Considering its advantages including high DBC, better alkali tolerance, low back pressure, high flow rate and good lot-to-lot consistency, the launch of AT Protein A Diamond Ultra will significantly boost productivity of pharmaceuticals via more efficient production of antibody drugs.

.png)