The Application of Chromatography Technology in Insulin Production

Diabetes is a metabolic disease featuring high blood sugar. Currently, approximately 0.11 billion of people are suffering from the disease in China, with 20%~30% of them requiring regular insulin injection to control blood sugar. The majority of currently available insulin is obtained via genetic engineering synthesis and subsequent purification process, among which, chromatographic technology is most widely used.

What is insulin?

Insulin is a protein hormone secreted by the pancreatic islet β cells in response to some substances, which can be both endogenous or exogenous. Examples of such substances can be found in glucagon, ribose, lactose, arginine and so on. Insulin lowers blood sugar levels by promoting the synthesis of glycogen, fat and protein, while being the only hormone in the body to lower blood sugar.

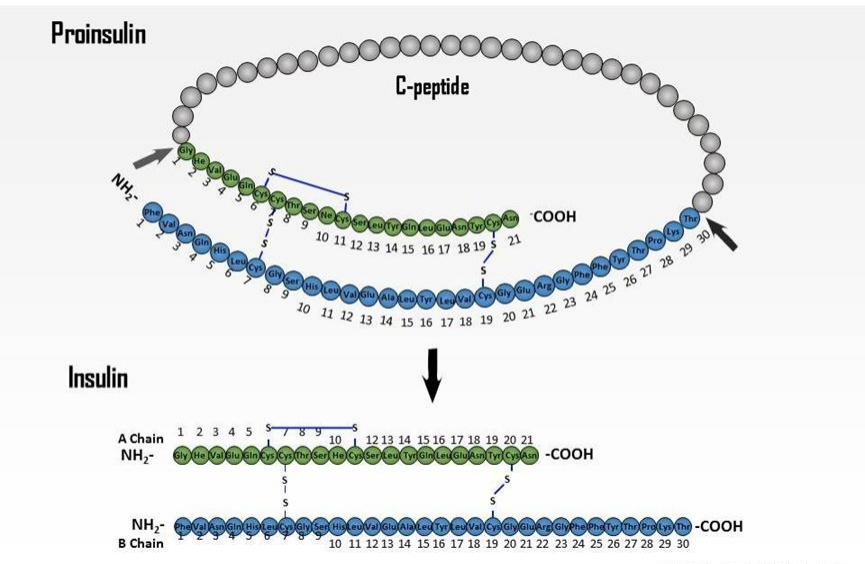

Fig. 1 Structure of insulin

Difference of Insulin analogs

|

Name |

Human insulin |

Insulin aspart |

Insulin lispro |

Insulin glargine |

Insulin detemir |

Insulin degludec |

|

Difference |

Position 21 aspartic acid

Position 29 Lysine

Position 30 threonine |

Position 28 replaced with aspartic acid |

Exchange amino acids at position 28 and position 29 |

Position 21 replaced with glycine,add Arg Arg at position 30 |

Position 2 lysine linked with 14C adipose acid |

Position 30 replaced with glutamic acid, position 29 linked with 16C fatty acid chain |

|

Effect |

/ |

Increase solubility |

Take effect rapidly |

Prolonged half-life |

Prolonged half-life |

Prolonged half-life |

Process

Insulin used for clinical trial is derived from three sources:

1. Animal insulin (extracted from the pancreas of pigs and cattle, two-sourced insulin enjoy same efficacy. Compared with human insulin, pig insulin has 1 different amino acid while bovine insulin has 3 different amino acids, making it easy to produce antibodies)

2. Semi-synthetic insulin (Replace position 30 alanine of pig insulin with threonine from human insulin, getting semi-synthetic human insulin).

3. Recombinant artificial insulin (Obtain high-purity biosynthetic human insulin via bioengineering technology, enjoying exactly same property as human insulin in terms of amino acid sequence and biological activity). Method 3 is considered the optimal method with the mildest side effects, as well as simplicity and safety in synthetic process. Therefore, the following studies were conducted for the preparation of recombinant artificial insulin.

Animal insulin

Extract insulin-acid alcohol from animal pancreas.

· Tradition insulin- extract from pig and cow pancreas via one step recrystallization

· Single-peak insulin- SEC purification

· One-component insulin-SEC and IEX purification

Semi-synthetic insulin

Semi-synthetic insulin—On the basis of pig insulin, obtain human insulin after enzyme modification.

Enzyme modification method refers to pig insulin enzymatic transformation method:

Achromobacter Lydicus protease can specifically catalyze exchange reaction of amino acids on carboxyl terminus(position 30)of insulin B chain, alanine(Ala) on the position 30 of pig insulin is is replaced with threonine(Thr) of human insulin. Under the influence of Achromobacter Lydicus protease, first remove alanine(Ala) on the position 30 of pig insulin via hydrolysis, get pig insulin with alanine-B30 removed, couple pig insulin with threonine(Thr) butyl ester, finally get human insulin by removing butanol with (trifluoroacetic acid)TFA and benzaldehyde.

Recombinant artificial insulin

AB chain synthetic method

Link the synthetic human insulin A chain and B chain genes respectively to galactosidase gene to form fusion genes,the A chain and B chain were expressed in Escherichia coli respectively,then linked by disulfide bond through chemical oxidation.(The method is outdated).

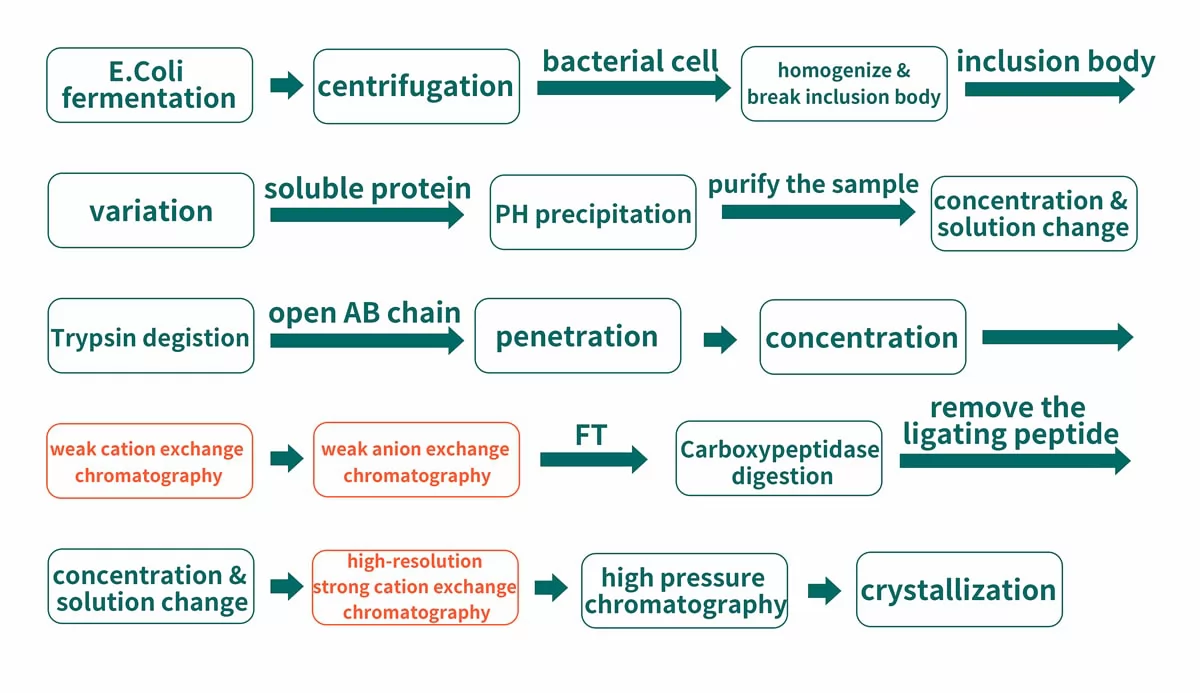

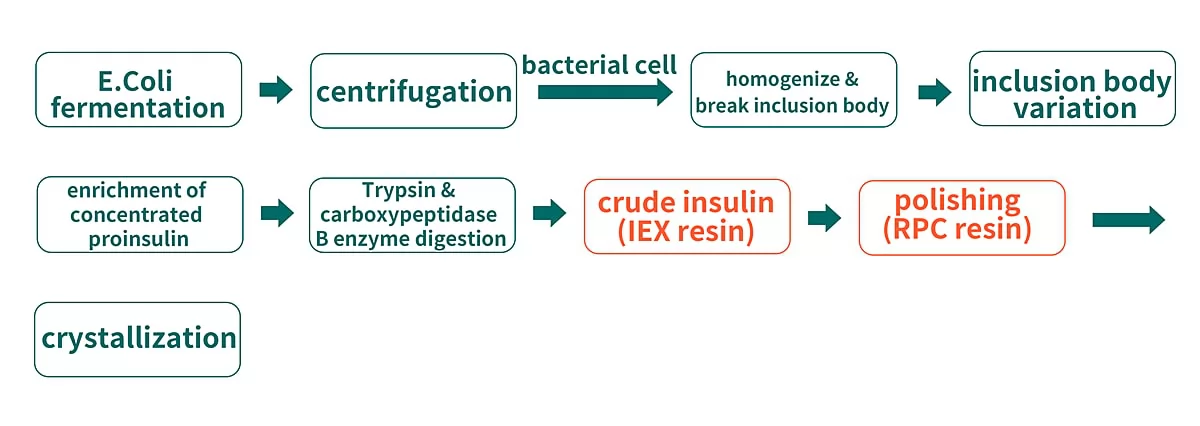

Process:

Reverse transcriptase method(mimic natural synthesis pathway )

Through synthesis of proinsulin cDNA, the expression product is proinsulin, which is dissected via enzyme,remove C peptide and obtain human insulin.

Process:

|

Resin |

Type |

Pack size |

Cat.No. |

|

Q Bestarose FF |

AEX |

25mL |

AI0021 |

|

DEAE Bestarose FF |

AEX |

25mL |

AI0031 |

|

SP Bestarose FF |

CEX |

25mL |

AI0011 |

|

CM Bestarose FF |

CEX |

25mL |

AI0041 |

|

SP Bestarose HP |

CEX |

25mL |

AI0080 |

|

BestPoly 15RPC |

RPC |

25mL |

AR400005 |

|

BestPoly 30RPC |

RPC |

25mL |

AR400105 |

Reference

1. Sims, Emily K et al. “100 years of insulin: celebrating the past, present and future of diabetes therapy.” Nature medicine vol. 27,7 (2021): 1154-1164.

2. Wright JR Jr. Almost famous: E. Clark Noble, the common thread in the

discovery of insulin and vinblastine. CMAJ (2002) 167:1391– 6.

3. Oubre AY, Carlson TJ, King SR, Reaven GM. From plant to patient: an

ethnomedical approach to the identification of new drugs for the treatment of NIDDM. Diabetologia (1997) 40:614– 7. doi: 10.1007/s001250050724

4. Zhong Songyang, HU Jie, Zhu Suwen. Common problems and countermeasures in insulin product consultation [J]. Chinese Journal of Clinical Pharmacy, 2011, 20(2): 119-121.

.png)